A quart of fiberglass resin and a pack of fiberglass cloth. And a couple of paint stirrers, and the most important thing of all, blue nitrile gloves. The gloves were an afterthought. I had no idea just how sticky this afternoon was going to be, so I'm really glad I picked them up.

Start off with a pic of the resin:

I used the plastic solo cups because I already had them in hand. I had no idea that when the resin finally kicks (chemically sets) it gets hot enough to melt the cup.

Here's my test cup. I used a measuring cup to add 4oz of water to the cup, then marked the level. I also marked 8oz, just in case 4 wasn't enough.

Doing that allowed me to know how much resin I was adding to the cup, so I would know how many drops of liquid hardener to add. The can says "for small repairs, add 10 drops to 1 ounce" and "working time will be 10-12 minutes".

For my first cup I added 4oz of resin and 36 drops of hardener. That didn't give me time enough to use about half of the resin.

For the remaining cups I used more along the lines of 7 drops per ounce, which did give me time to use most of the resin.

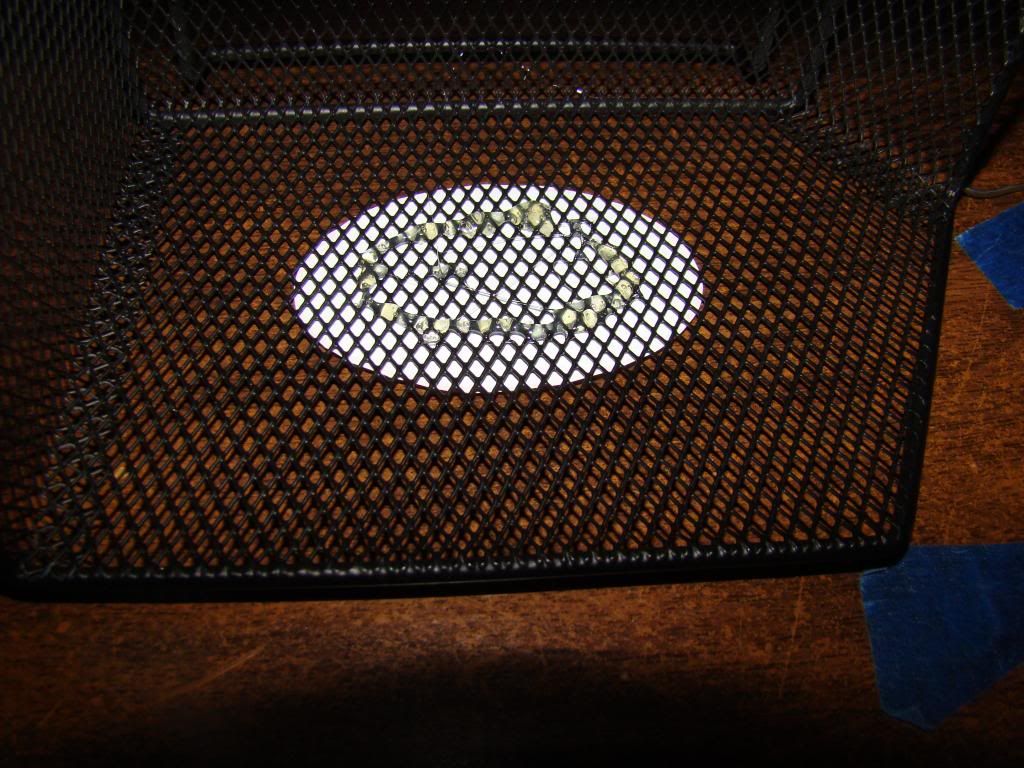

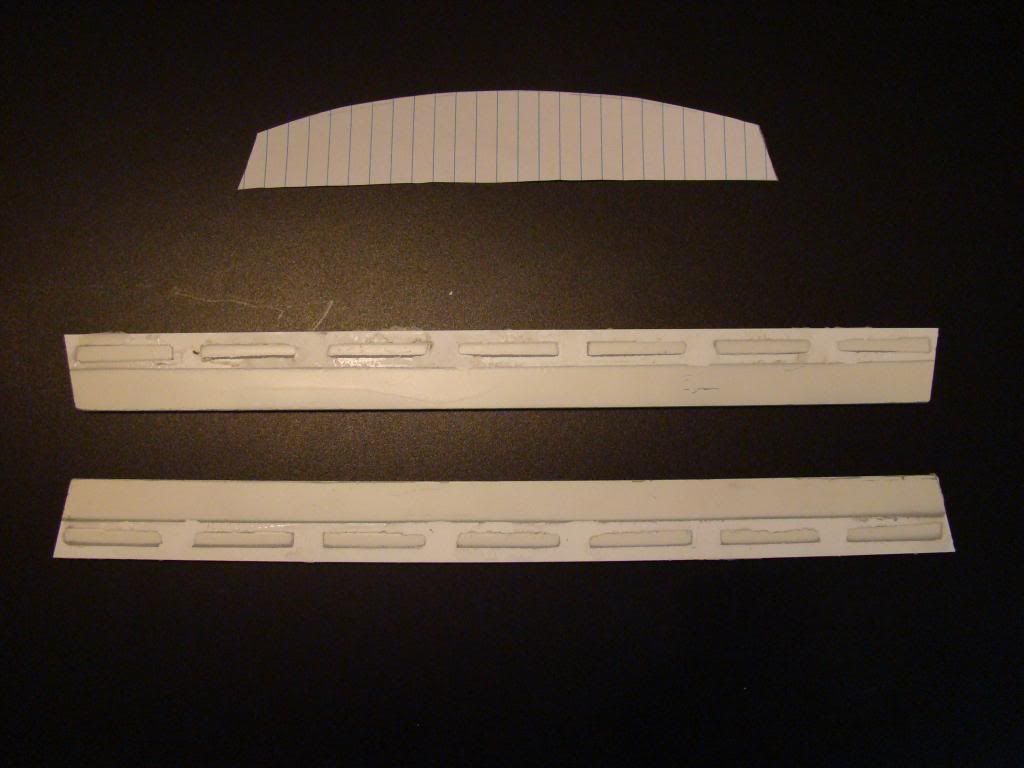

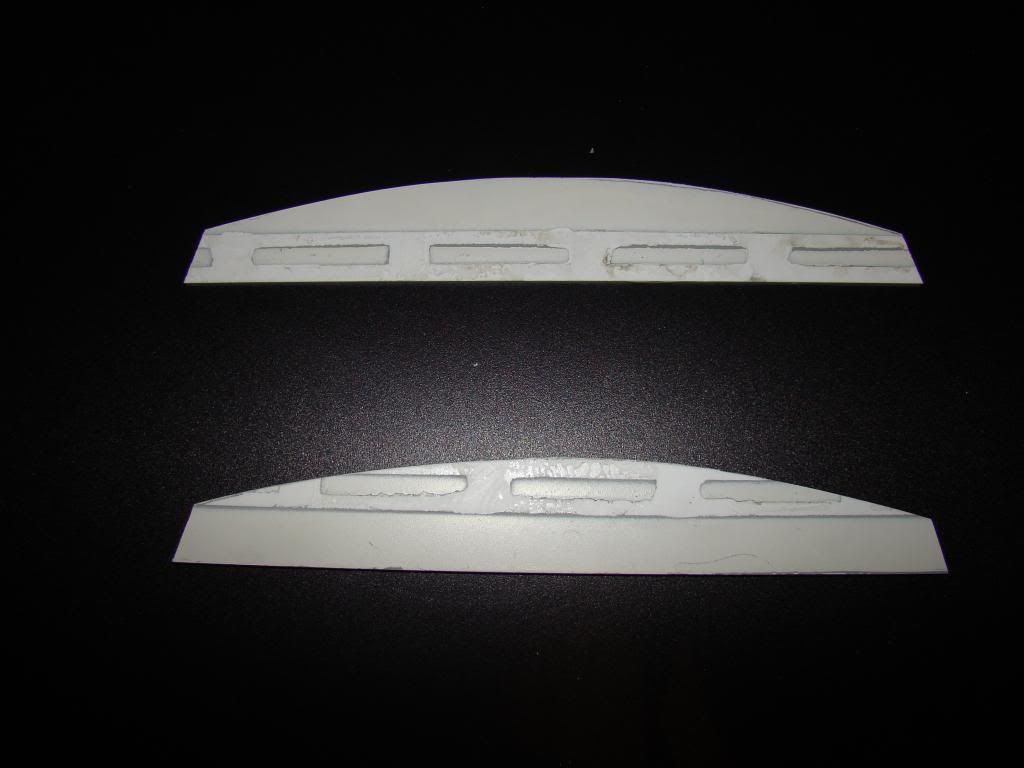

Here's a shot of several pieces of cloth cut to length for the seams.

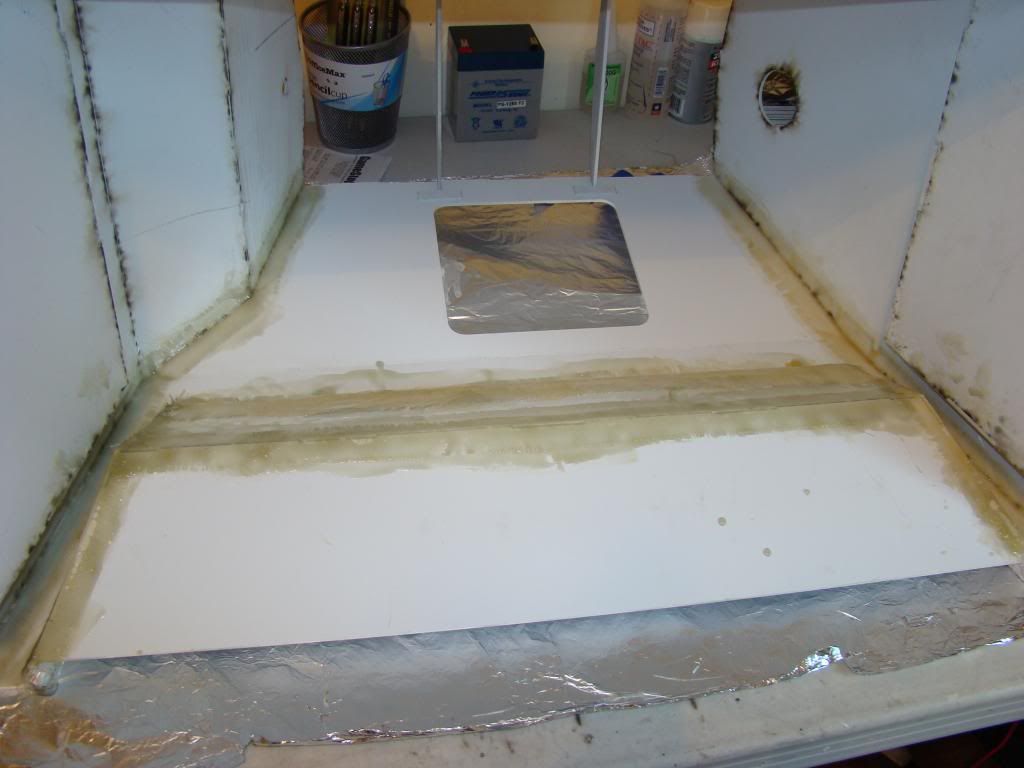

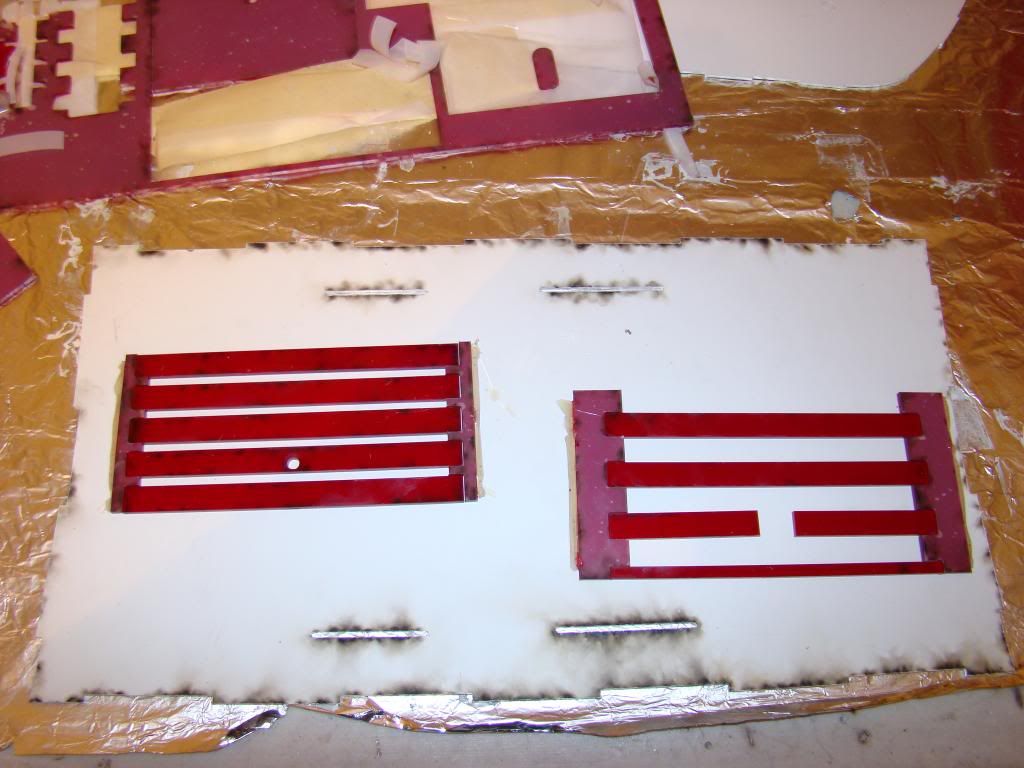

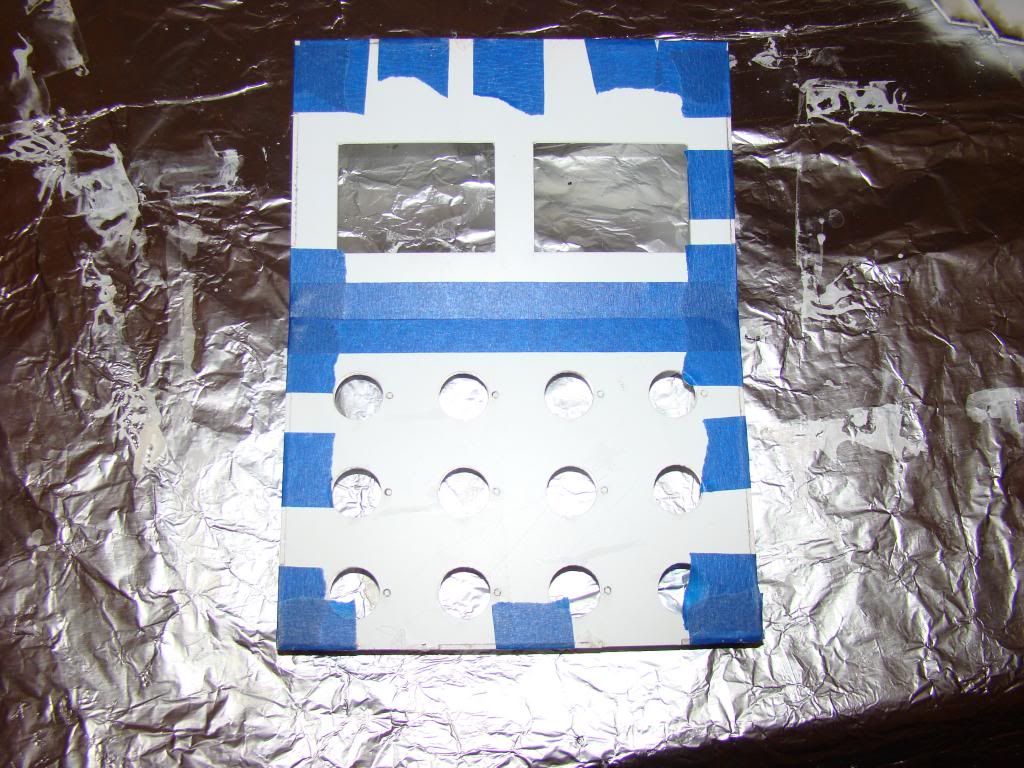

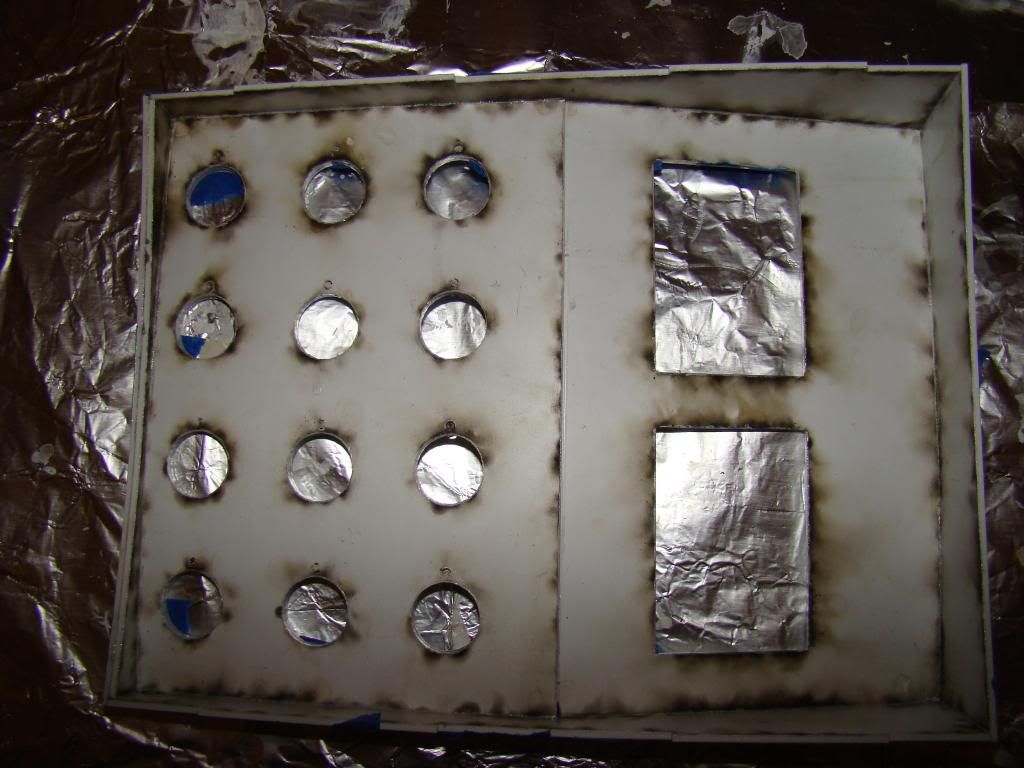

And several shots of finished seams:

I'll say, it's not a very pretty job, and it was pretty darn messy. I'm pretty confident that my weak seams issue will be solved with this. I just wonder what that's going to get in the way of at a later date. I know I can drill through it for mounting thing like the handles and the neck and tail mounts, so I'm hoping the answer to that question is not too much.

Maybe later this evening I'll get some of the work I'd planned on doing before the damage occurred. Only 2 days lost...at least there's not currently a deadline. Yet. :)