Ok, as promised, going to try to explain the whole RC thing. At least the dome motor and drive motors part.

As a note before I start, the hardware I'll describe is pretty close to what I plan on using. Other stuff might be different...

We'll start with the transmitter. Mine's going to be the Futaba 6EX. That seems to be the most popular one.

The drive motors will be controlled by the left joystick, using what's called "mixed mode". I don't know exactly how it works, but Droidwelder gives a description

here. The means that both motors will be controlled by one joystick, using channels 1 and 2.

The right joystick will be for spinning the dome one way or the other using the side to side (probably channel 4).

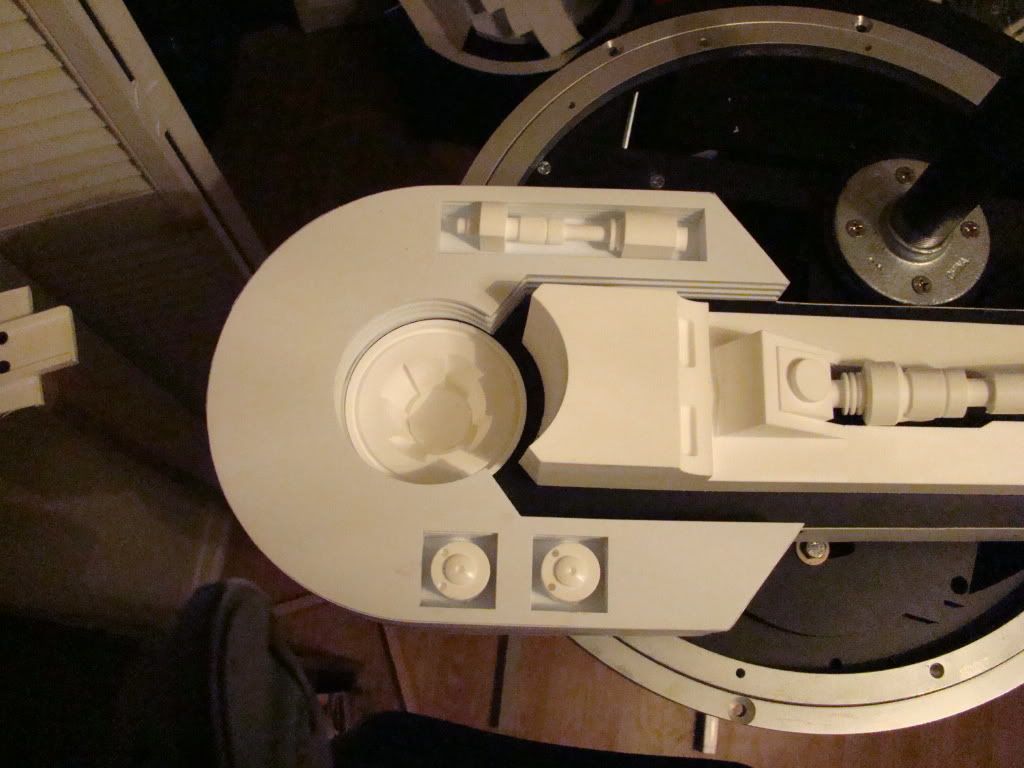

So, when you use the joystick on the transmitter, it sends the signal to the receiver, which will look a lot like this:

Receiver

ReceiverWhen people refer to "channel 1" or "channel 3", those correlate directly to the numbered plug holes on the receiver. So far, our signal has gone from the joystick, out the antenna, to the receiver and to the 3 wire plug hole you see above. They are also sometimes keyed, so you can't plug them in backwards, which would make the motor run backwards.

Next up is the speed controller. A speed controller is exactly like a dimmer switch for a light bulb. News to me, instead of limiting the power like I thought it would have, it switches the power on and off really fast. How fast depends on the position of the switch (in this case the signal). So apparently a dimmer switch turns the light on and off so fast that the filament doesn't have time to warm up completely. Supposedly from an electronics standpoint this is far more desirable, because it produces less heat and stuff. I'll take "their" word for it... It also produces that hum you might hear from a dimmed light sometimes.

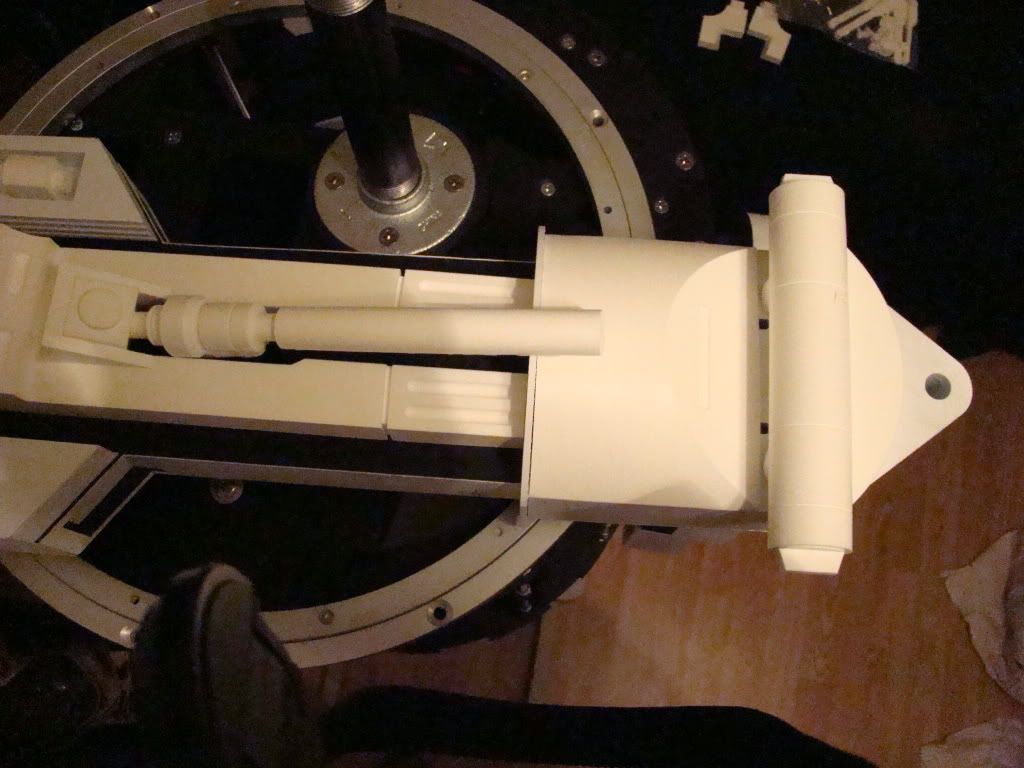

The Scorpion XL speed controller looks like this:

Scorpion XL speed controller

Scorpion XL speed controllerLooking at this picture is where everything kinda clicked for me...You can see the 3 sets of 3 wires with the little plugs. Those go to the receiver. Offhand I'd have to guess that the one labeled "right" goes to the channel 1 output, the one labeled "left" goes to the channel 2 output.

And now for a quick break to explain what I think the one labeled "comm" does. On the bottom left side of the board, you'll see something labeled "BEC". This is the connection for the "Battery Elimination Circuit". What this does is provide 5v of power, so that you don't need a power source for your receiver. My only slightly more than un-informed guess is that the set of wires labeled "COMM" will plug into the port for output 8, which is labeled in red in the first picture, thus eliminating the need for a battery for the receiver.

By now things are probably starting to click. The motors will attach to the appropriate screw-down block. The power from your battery (Or power distribution board/fuse block) will attach to the top set of screw-downs. BTW "screw-downs" probably isn't the correct terminology for those parts, it's just what comes to mind without having to research what it really is.

The dome motor will work almost exactly the same, but it will have it's own speed controller, and will use channel 3 or 4, depending on how the transmitter is set up.

I was also told that under no circumstances should you use the BEC from both power boards. One will suffice.

Ok, so that's what I know about RC so far. You'll notice there's an awful lot of "I think" and "probably" going on in there...if I'm not right about something, please don't hesitate to speak up. Better to have to edit a post than replace a part that blew up because I connected it wrong. But that should be enough to clear up a little bit of the mud.

It sure does sound a lot like red wire black wire, doesn't it? Plug it into the right place and it goes...plug it in wrong and it either doesn't go, or it goes backwards :P

Oh, before I forget, a big thank you to Droidwelder over at astromech.net for answering questions for probably the umpteen thousandth time...

Receiver

Receiver Scorpion XL speed controller

Scorpion XL speed controller