So, about a month ago I started doing my "DragonCon checkups" on R2. Some of you may recall the "Cleveland R2" wig I made for DCon last year. Leaving the wig on R2's dome for an extended period of time caused an ugly problem. There's apparently some sort of chemical that leaches out of the marine vinyl that I used as a base for the wig. It caused the clear enamel Rustoleum that is the top coat (or 3 top coats) to become thick and gummy.

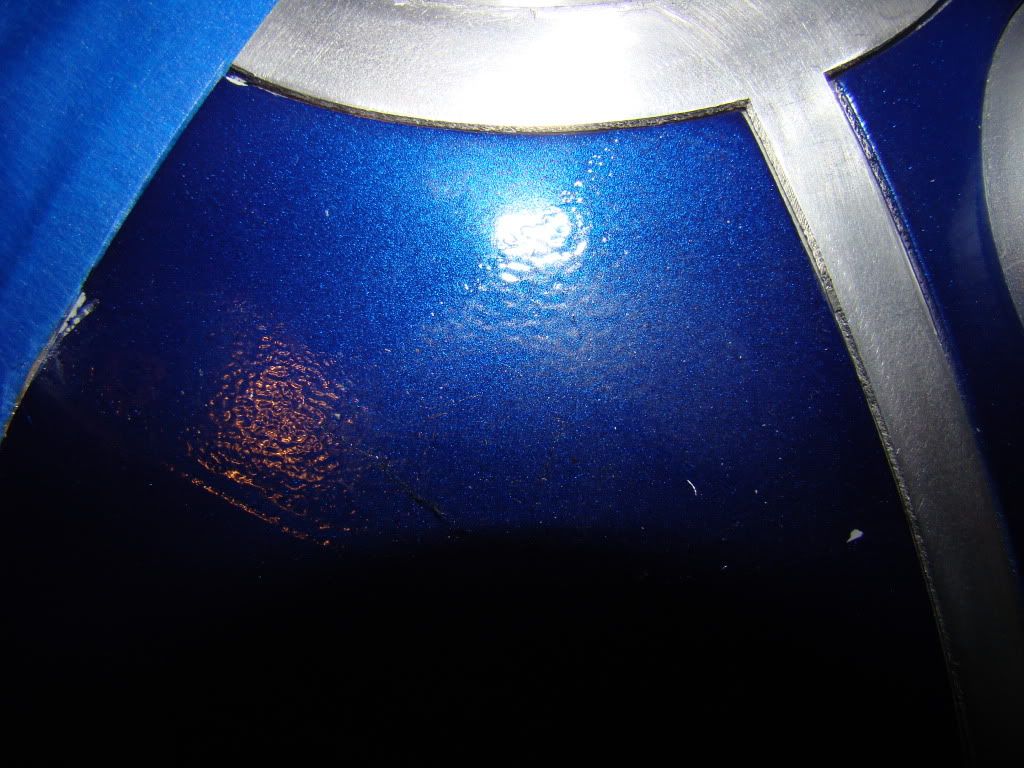

Here's a shot:

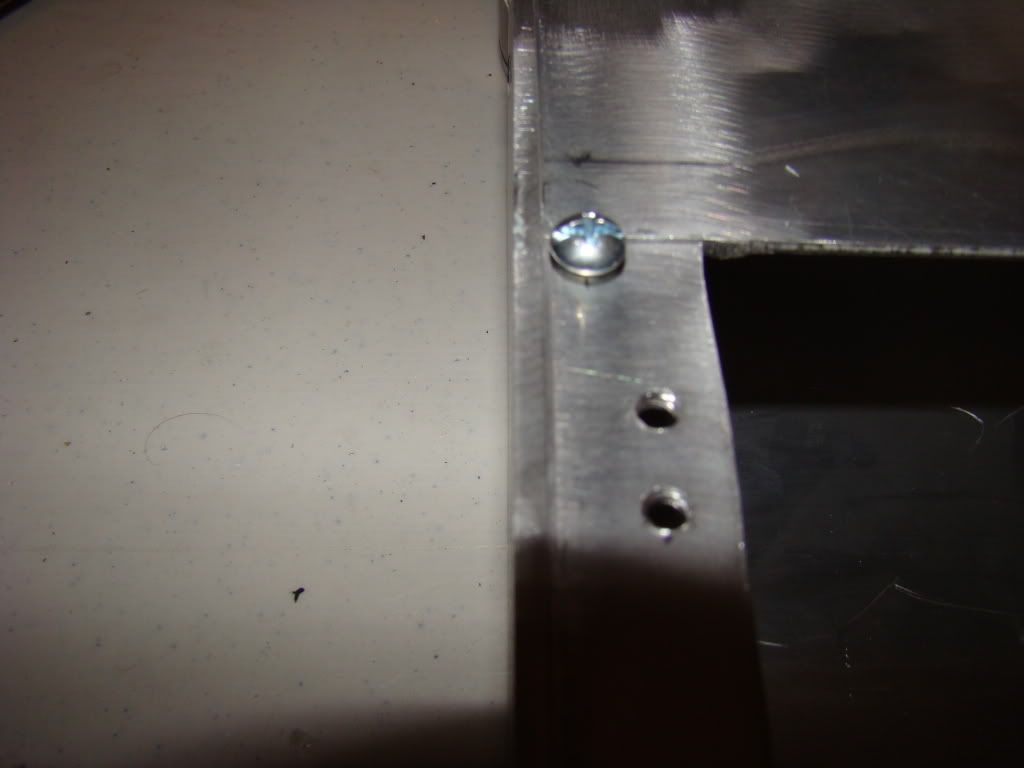

You can see it's kind of ugly. The panels were originally attached with silicone. I decided the safest way to remove the panels without major damage was to use one of the flexible thin steel rulers.

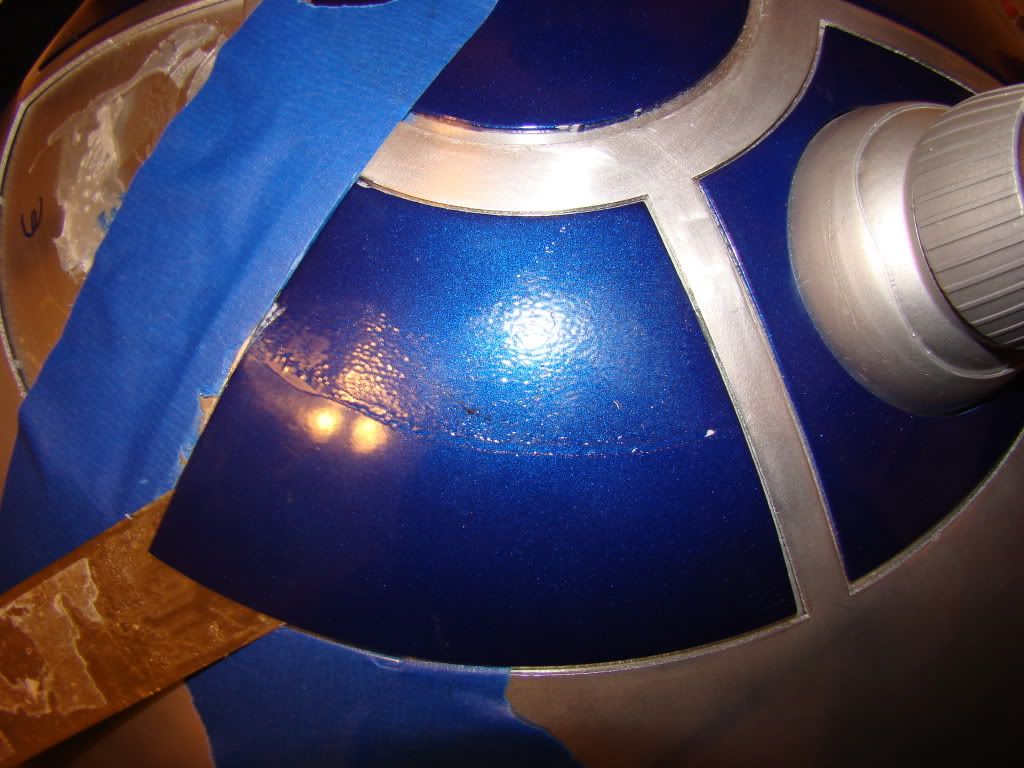

I think it was $2 at the good ol' Harbor Freight. After taping the dome to try to avoid extra damage, I pried up the bottom corner of the panel just enough to slip the ruler underneath. I then hammered the ruler through the silicone until the panel popped off.

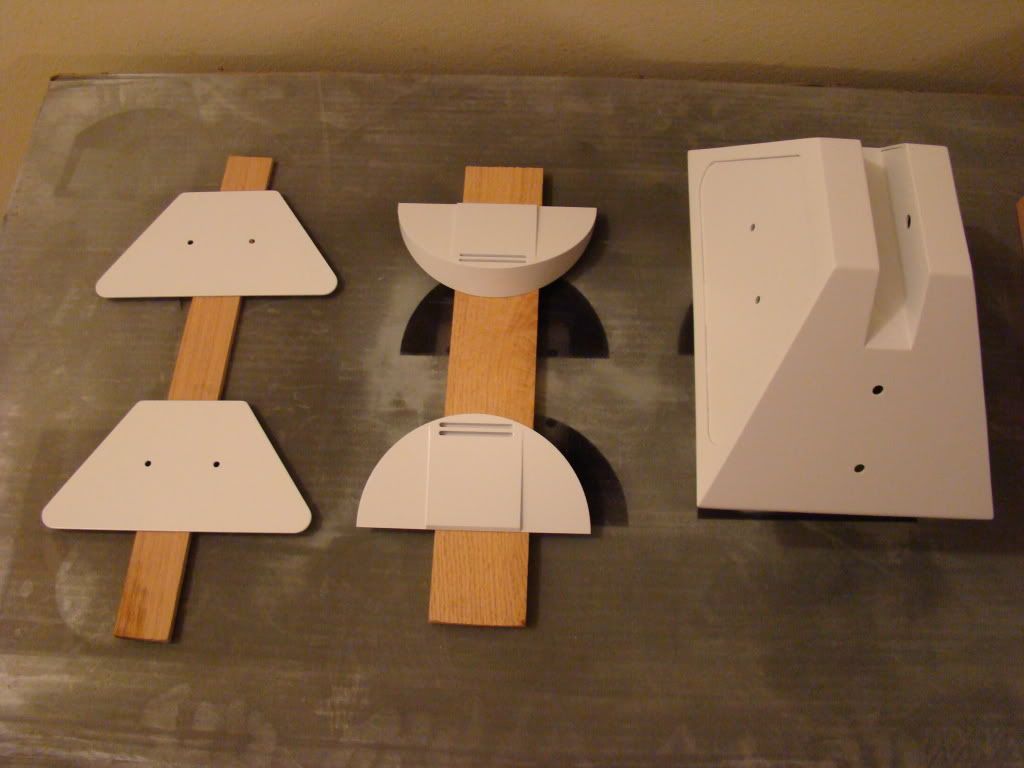

The panels were slightly warped from prying up the corners, but that was nothing that some tapping on the back of the panels while held in my hand couldn't fix. Next, I had to old silicone to deal with. I basically just "worried" it off with my thumbnail while watching TV to make the time pass. Here's a shot of what I had to work with:

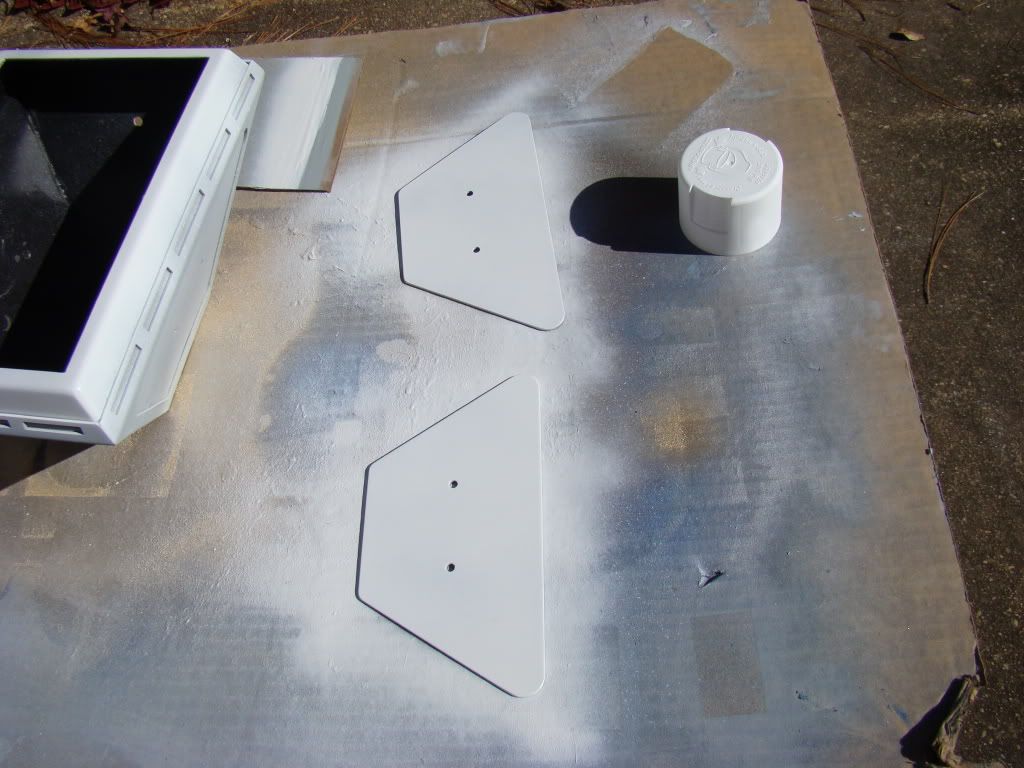

Next up, I posted on FB asking if any other builders had any experience removing the paint, but got no replies. Must have been a bad time of day to post. Anyway, I checked on Astromech.net, and only found one post about removing krider paint in the last 3 years. It suggested "acetone and a clean soft cloth". I gave that a shot, but the cloth didn't even really turn blue with "vigorous rubbing". That meant I wasn't even getting through the clearcoat, which granted, is probably 4 coats thick. My next plan was more daring. I stopped by the Neighborhood WalMart and picked up a $5 2-quart aluminum saucepan. Once I got home, I checked the kitchen cabinets to find I had an old saucepan already. Can you say "upgrade"? Anyway, as a test I poured about a half an inch of acetone into the pan, then put the top middle "donut" shaped panel in to soak. After a couple of minutes, I found I was able to just rub the paint off of the piece. The strange thing was the Duplicolor Blue and it's reaction to the acetone. It really didn't dissolve like the clear and the metallic blue did. It remained stringy and gummy the whole time. I added about another 2 inches of acetone to the pot, and proceeded to clean the remaining pieces. As soon as I started working on the first piece, the acetone turned the prettiest metallic blue color you've ever seen. When a new piece was added it would begin swirling around in the pan all by itself.

Anyway, after each piece had been cleaned, I rinsed that piece in cold water and set it aside. Once all the pieces had been cleaned, I then disposed of the old acetone and poured an inch of fresh acetone into the pan. I then gave each piece another bath, to remove anything the previous bath didn't get, then another bath, this time in warm water with dishwashing soap (Would've been Dawn, but the store was out last time I bought dish soap, so it was actually Gain) and a light scrub with a scrubbing sponge.

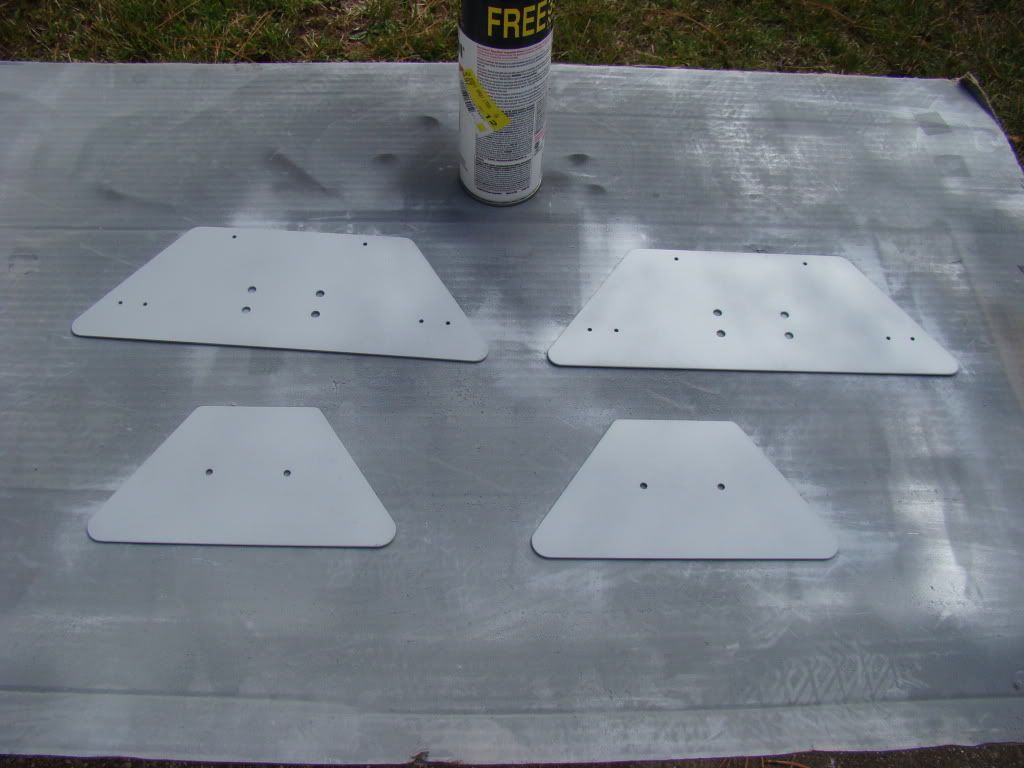

I think the oddest things of all are that the acetone didn't remove what was left of the teflon in the old pan, and that the acetone ALSO didn't remove the primer from the panels. I believe if I'd had something to scrub the panels with in the 2nd acetone bath, it might have come off.

The spots where the primer did come off were places where the panels had been scratched or chipped, and so the acetone was able to get into the primer better. Or at least that's the theory i'm gonna go with. Next step will be to let the panels sit overnight and completely dry. I toweled them dry, but I'm being lazy at this point. Tomorrow I'll sand them lightly then apply another coat of primer, which will cure tomorrow night. MAYBE it won't rain on Saturday, and I'll get to repaint...